2.2KW Air Cooled Spindle Motor

ER20 Collet & Four Bearings & 12000-24000 R/min

These spindle motors adopt imported bearings and high-quality stainless steel materials, and their service life is three times that of ordinary spindle motors. Widely applicable to engraving machines for wood, stone, metal, and other materials.

- Technical Parameters

- ER20 Standard Collet

- Powerful Bearing

- Low Noise & Heat Dissipation

Dynamic Balance Design

Unlike other milling spindle motors, we use innovative and advanced dynamic balancing technology. The ER20 standard collet's advantages are excellent rigidity, full strength, unique drainage design, and high precision.

Four High-quality Bearings

The upgraded bearing has two significant advantages: superior durability and anti-rust performance. High speed (12000-24000R/min) and strong power bring higher efficiency than before.

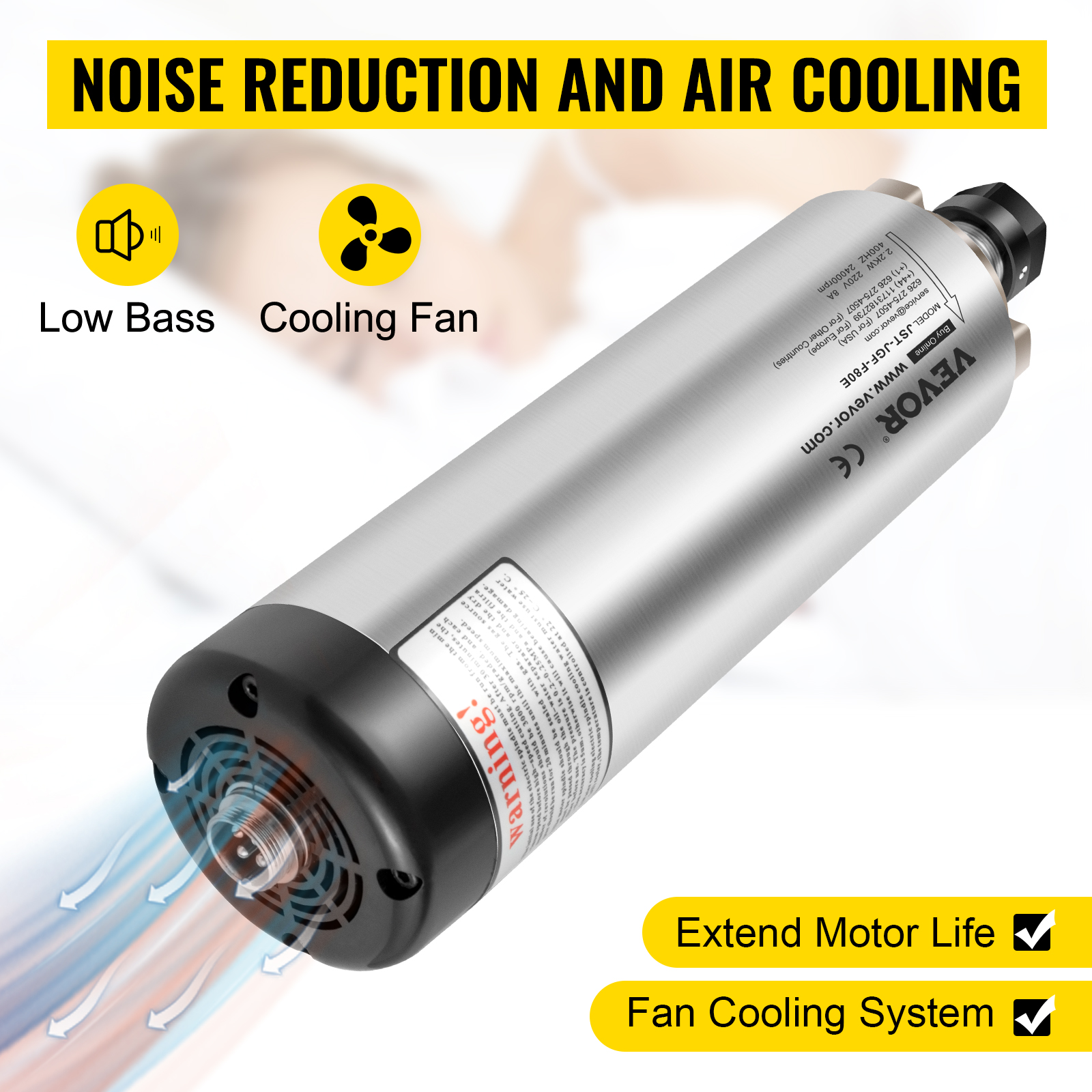

Noise Reduction and Air Cooling

Our CNC router spindle motor works with low noise and avoids auditory fatigue. It uses air circulation to cool the heat generated by the spindle at high speed and has a good heat dissipation effect.

Premium Material

The stainless steel body ensures greater power and longer life; Unlike ordinary aluminum-clad wire, the oxygen-free copper coils can ensure high-quality processing and engraving performance.

Refined Internal Details

The CNC router spindle is a built-in upgraded aviation plug, which is simple to make the current flow and achieve the predetermined function of the circuit, effectively improving the stable and smooth operation.

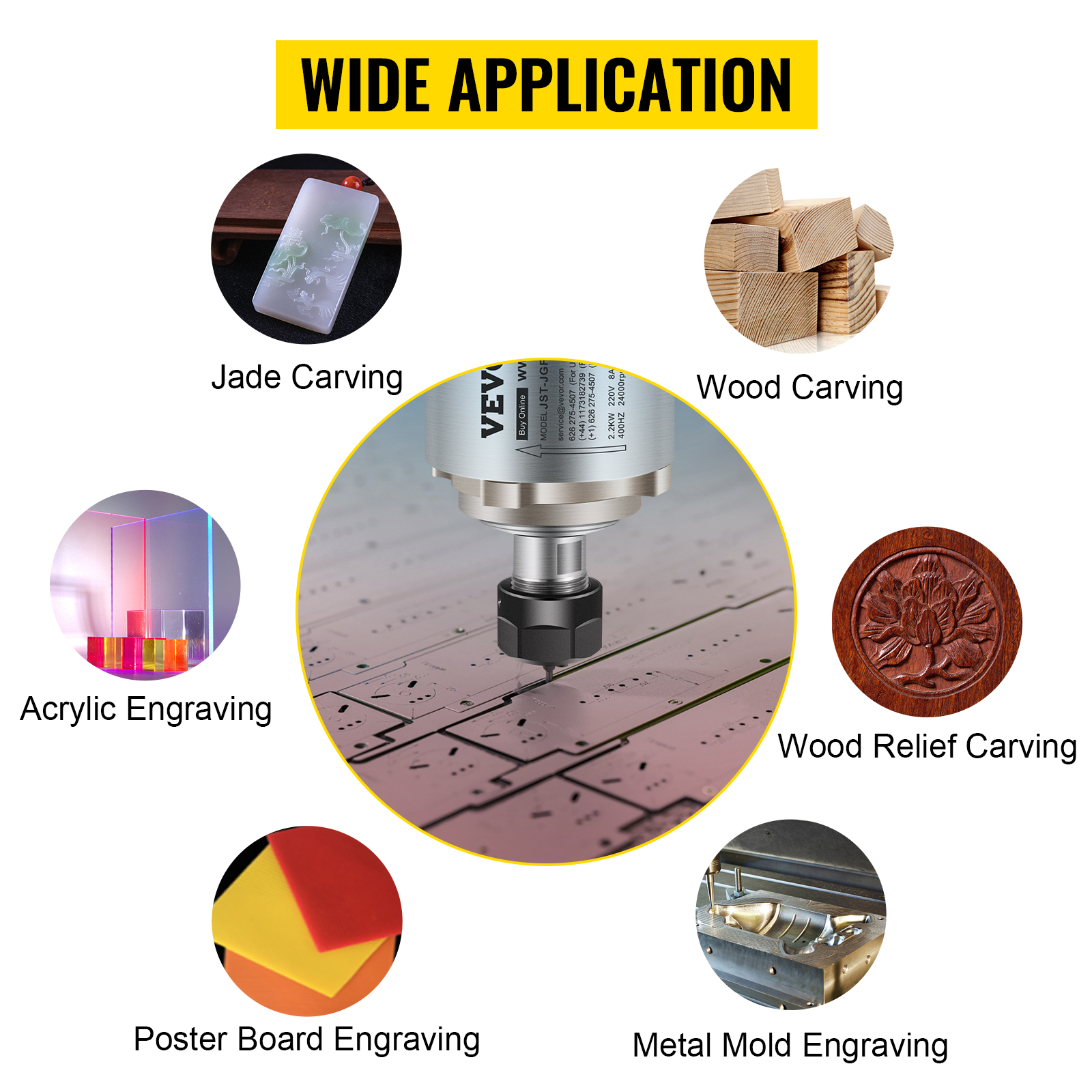

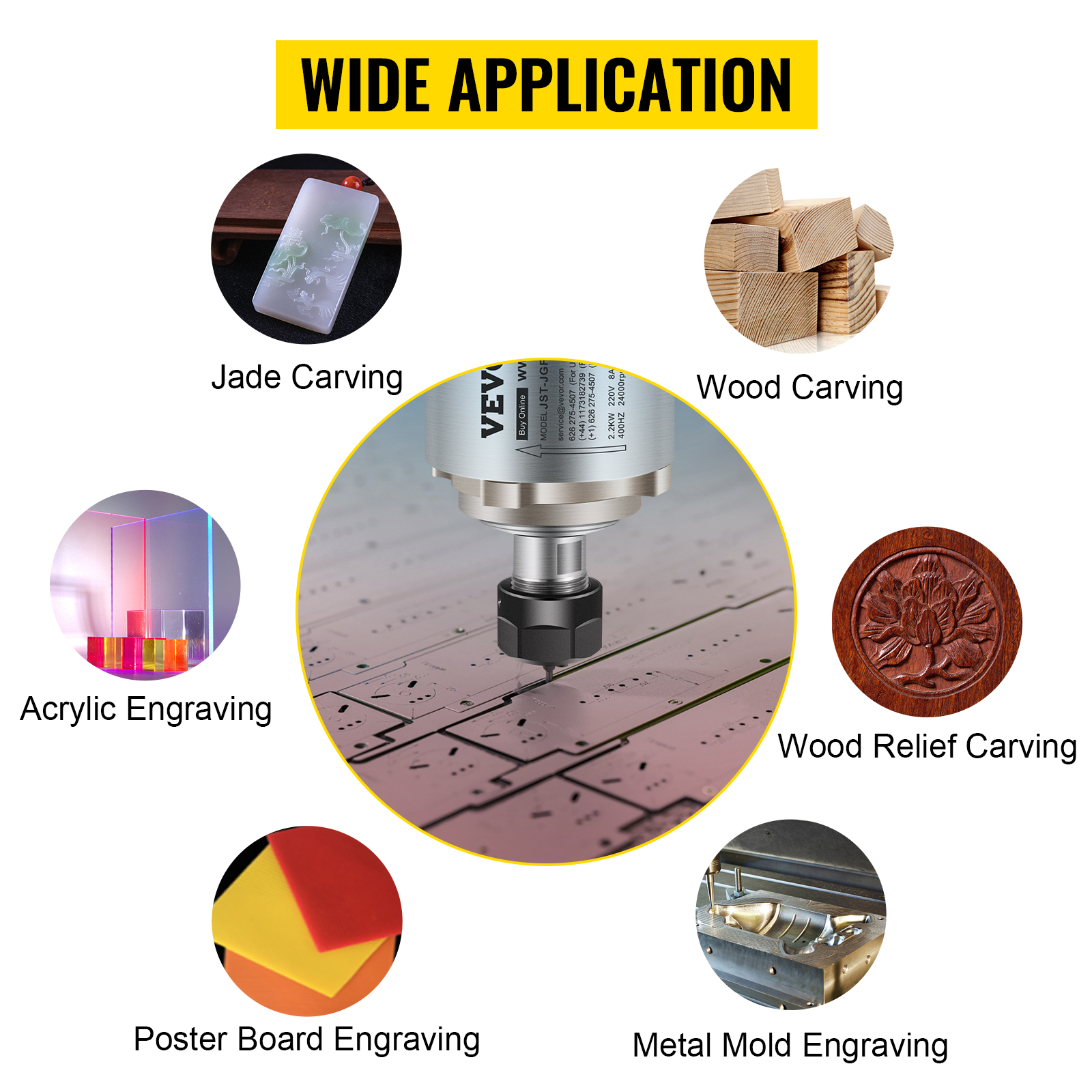

Wide Application

Air-cooled motors commonly applied materials such as wood, stone, mold & metal, etc. Suitable for machinery manufacturing, sheet metal processing, guardrails, factories, shipyards, home improvement, construction, and other fields.

- 1 x Air Cooled Spindle Motor

- Power: 2.2 KW

- Voltage: 220V

- Frequency: 200-400 Hz

- Speed: 12000-24000 R/min

- Runout off: Less than 0.002 mm

- Maximum Torque: 1.7NM

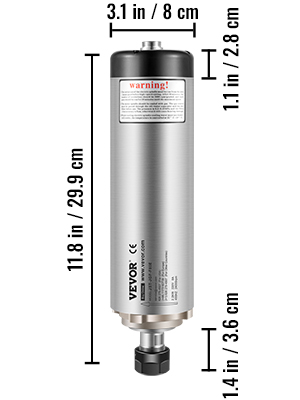

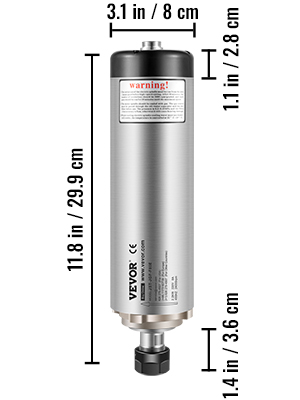

- Product Dimension: 3.1 x 11.8 in / 8 x 29.9 cm

- Weight: 13.2 lbs / 6 kg